Petrofast’s Oil and Gas Engineering division delivers integrated solutions that cover the full spectrum of the hydrocarbon lifecycle—upstream, midstream, and downstream. We provide engineering services that range from wellhead and production facility design to refinery upgrades, pipeline networks, storage facilities, and LNG terminals. Each project is executed with an uncompromising commitment to safety, performance, and sustainability, helping clients meet global energy demand in a responsible manner.

Our capabilities include process engineering, HAZOP studies, instrumentation and control systems, pipeline integrity management, modular skids, and plant shutdown services. With strong expertise in both greenfield and brownfield projects, Petrofast ensures that all systems are engineered to withstand high pressure, corrosive environments, and dynamic flow conditions typical of oil and gas operations. We deliver cost-effective, modular, and scalable designs that reduce CAPEX and OPEX without compromising safety or operational performance.

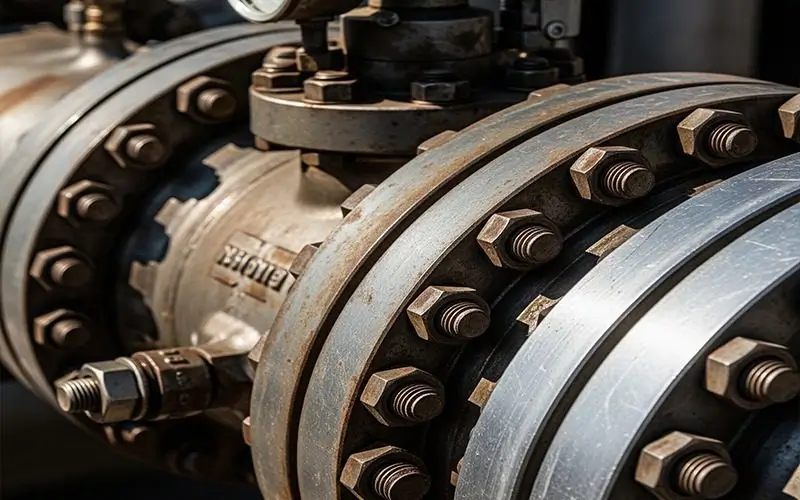

Fastening for Oil & Gas Engineering

Petrofast delivers specialized Oil and Gas Services through advanced fastening solutions for the engineering sector. Our products perform reliably in extreme conditions, including high pressure, corrosive environments, and temperature variations. We protect the integrity and safety of critical infrastructure, from pipelines to drilling equipment.

- Harsh Environment Durability: Fasteners with superior resistance to corrosion and stress, designed for critical oil & gas applications.

- Certified Integrity: Expert support to meet rigorous industry standards and ensure the safety and compliance of your systems.

- Comprehensive Range: A complete product line for heavy machinery, pipelines, and other complex oil & gas projects.

Research

The fastener industry often deals with challenges such as fluctuating raw material prices, meeting diverse international quality standards, and ensuring corrosion resistance for products used in extreme environments. Continuous innovation and strict quality control are essential to remain competitive.

We source high-grade raw materials and follow stringent manufacturing processes, including precision machining, heat treatment, and rigorous testing. Every fastener is inspected for strength, durability, and compliance with ISO and ASTM standards before leaving our facility.

Fasteners play a critical role in Oil and Gas Services by holding structures, machinery, and equipment together. A single faulty fastener can compromise safety and operational performance. Using reliable, high-quality fasteners ensures structural integrity, reduces maintenance costs, and extends the lifespan of oil and gas projects.